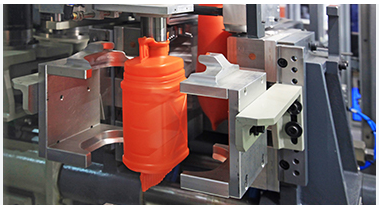

Rotational molding or Rotomolding can be a well-known developing procedure for producing complicated plastic-type parts that are too big being made by standard shot molding. One of the important benefits of Rotational Molding is it provides for a variety of supplies for use, every because of their exclusive qualities and benefits. Within this blog post, we’ll acquire a close look at Rotomolding resources, the different alternatives offered, and some key considerations when choosing the right materials for your software.

Polyethylene (PE)

Polyethylene is perhaps probably the most popular components in rotational molding. It’s a heavyweight, strong, and versatile fabric that is perfect for generating huge parts which require superb effect opposition and toughness. PE also offers a higher potential to deal with chemical compounds and Ultra violet rays, rendering it a great materials selection for backyard programs.

Nylon material

Nylon is a great materials selection for rotomolded components that need great durability, toughness, and dress in amount of resistance. It’s another wonderful fabric for creating parts which need low friction, for example gears and bearings. Nylon may be bolstered with glass materials to enhance its power and stiffness further more, rendering it a perfect substance to get more stressful manufacturing software.

PVC

PVC or Polyvinyl Chloride is actually a well-known selection for rotomolded elements that require exceptional chemical substance level of resistance. It’s another excellent fabric choice for producing huge components with intricate designs and fashoins. Pvc material might be formulated to get accommodating, rigorous or a mixture of equally, making it an ideal materials for a variety of software like piping, tanks, and liners.

Acrylonitrile Butadiene Styrene (ABS)

Ab muscles is a wonderful materials choice for rotomolded pieces which need a balance between energy, toughness, and firmness. It’s a versatile fabric that can be easily shaped which is suited to software such as car components, suitcases and circumstances, and playthings.

Cross-Associated Polyethylene (XLPE)

Cross-Associated Polyethylene or XLPE can be a higher-solidity polyethylene substance which has gone through a chemical substance method to boost its energy and gratifaction characteristics. It’s an ideal material for rotomolded elements which require increased tightness and improved temperatures level of resistance. XLPE is usually useful for developing components such as fuel tanks, kayaks, along with other underwater programs.

Concerns when deciding on Rotomolding Resources

When deciding on the best Rotomolding fabric for your personal pieces, many variables should be considered, including product style, substance components, and manufacturing process specifications. A few of the important considerations include:

Aspect dimensions and intricacy

Mechanized properties essential – power, overall flexibility, impact level of resistance, etc.

Chemical amount of resistance and UV stability

Temperature resistance

Expense

In a nutshell:

Rotomolding components supply a wide range of options dependant upon the distinct demands of your respective application. By selecting the right substance, it is possible to ensure your rotomolded components carry out optimally and endure the requirements of the app. Partnering using a dependable and seasoned Rotomolding company is likewise crucial in ensuring that your pieces are created for the greatest standards of good quality and accuracy. If you’re seeking to get began with Rotomolding or require assistance deciding on the best material to your software, contact us these days!